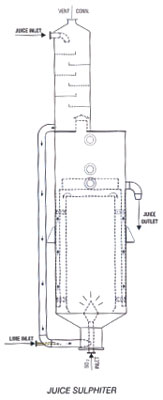

Sugar Plant & Spares  CONTINUOUS JUICE SULPHITORS

CONTINUOUS JUICE SULPHITORS

Sulphitation of juice is the key to the entire process of a Sugar plant, be it for better quality of sugar or reduced viscosity in malasses and massecuite.

A good design needs to incorporate pre and shock liming as well as, make the equipment capable to deal with refractory juices also. The SS juice Sulphiter has been designed with unmatched innovative features to take care of all the requirements of a good sulphitation.

Main Advantages :

- The pH of juice is observed at three places during the process and the addition of lime and SO2 gas is adjusted accordingly, thus the process control is better.

- Optimum quantity of lime is added to the juice first and then SO2 is added for desired sulphitation PH.

- Pre-liming or Pre-sulphitation and shock liming and sulphitation is carried out as per the process requirement and juice quality.

- Complete absorption of SO2 gas takes place due to gas and juice contact time over 10 seconds provided due to 3.5 M level of juice above gas outlet sparger.

- The flow of gas and juice is streamlined for maximum circulation & then ensuring proper mixing with 15 fold circulation without stirrer on air lift principle.

- Design is flexible to adopt different processes, i.e. Pre-liming or pre-sulphitation or simultaneous liming and sulphitation etc.

- No moving parts and hence very low maintenance.

- No power requirement.

- Compact design.

- Less scaling in evaporators due to less rise in CaO content from mixed juice to clear juice.